Well, now that you know how to get the database setup for the SCE UI, you need to work on creating the knowledgebase. This is pretty straightforward exercise, but it does require a few transactions to perform the whole process. Let’s walk through what you need to do.

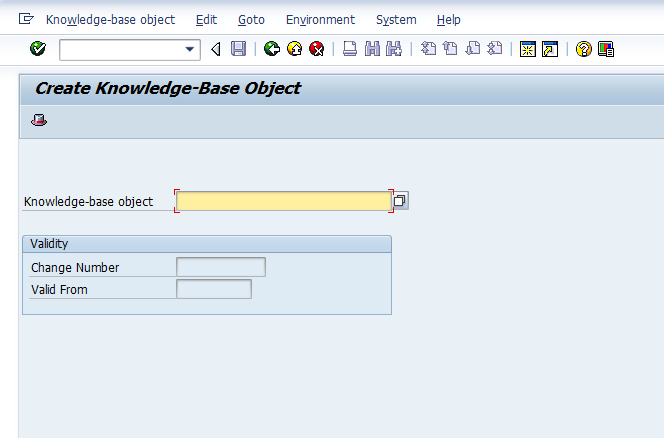

We start with Transaction: CU31 to create the KB object.

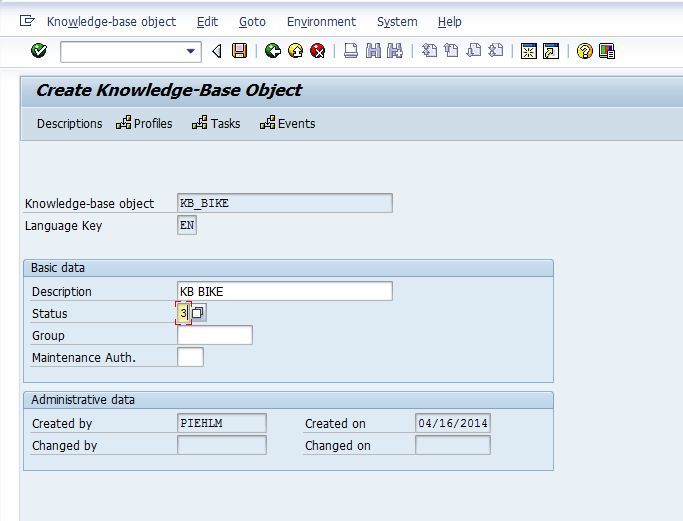

Much of the information is just descriptive, so set the status and give it a description. THen press the profiles button.

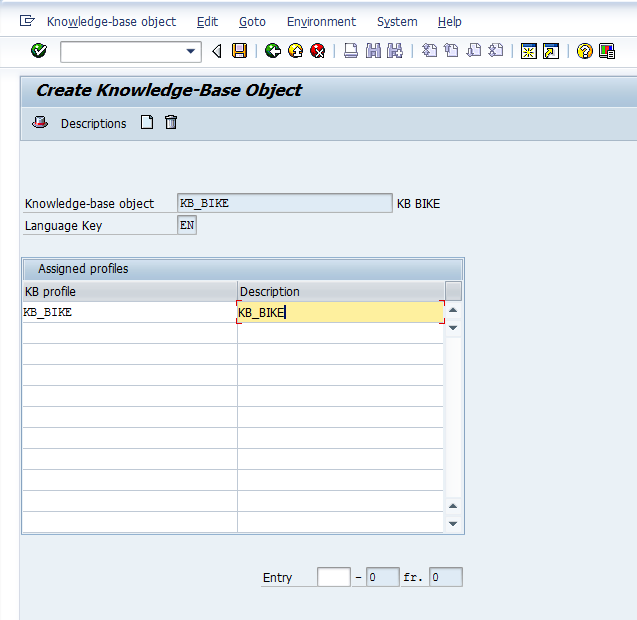

Again, these are just names, so name the Profile and give it a description. Then press enter.

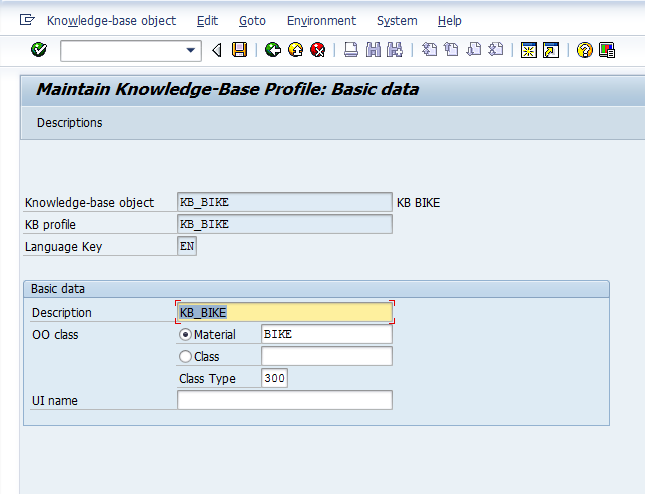

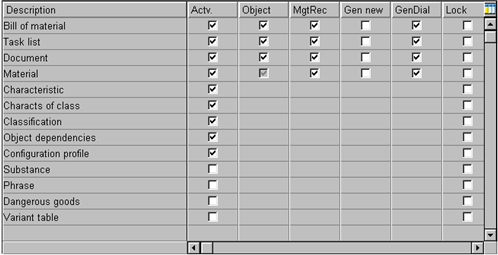

Now, we finally get to some real data. I typically enter in the KMAT material, but you could do it by class and class type. Add a description and then save.

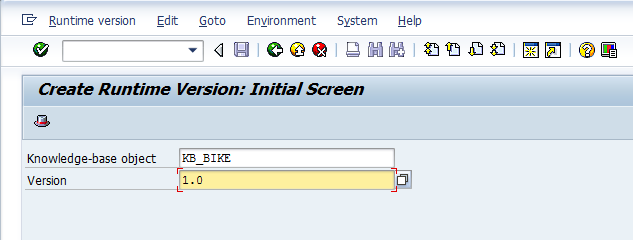

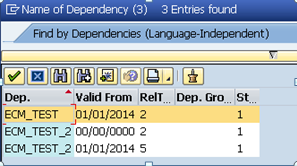

Now that you have a knowledge base, you can create the runtime version (RTV). Go to transaction CU34.

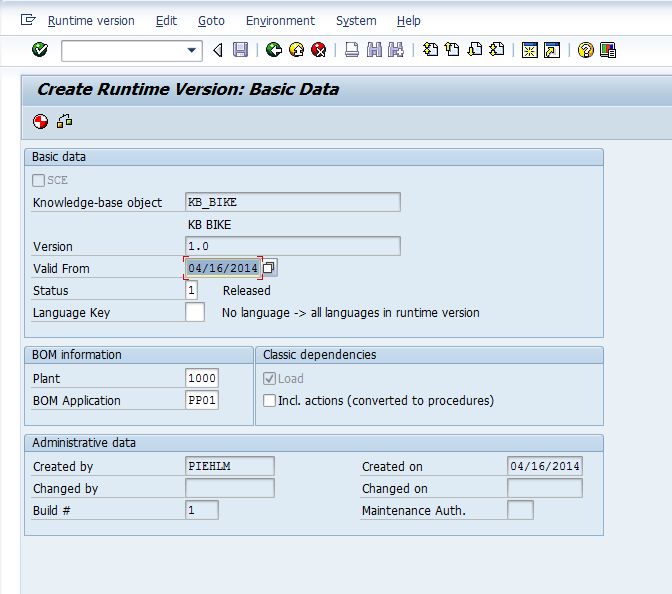

IN this screen, we set up all the vital stuff, including what plant the BOM should be looking at, if it’s a production BOM or Sales BOM, etc… Also, a very important field is the valid from date. Remember, that KB’s and RTV’s have no concept of engineering change. This means that the valid from date is VERY important for your process going forward.

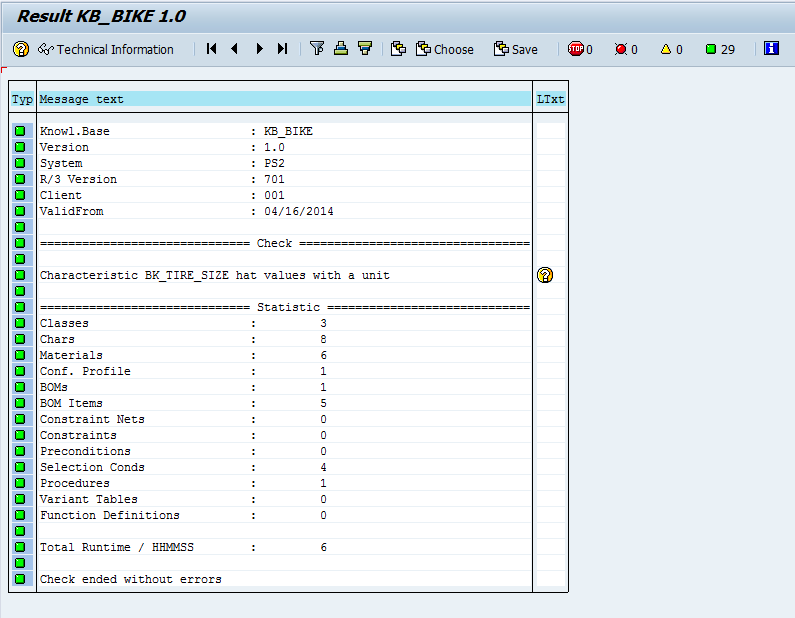

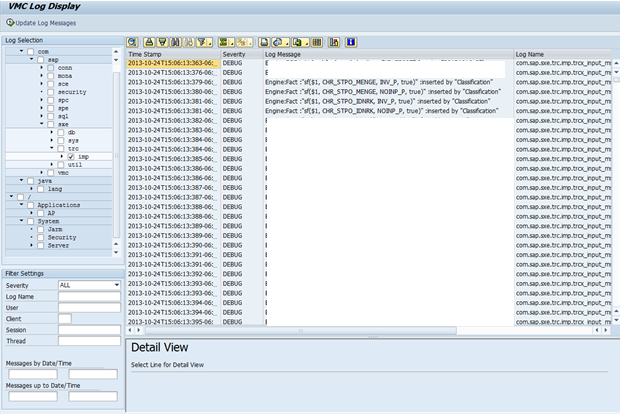

After you enter in the info, I encourage you to check. Press the syntax check button, and you will receive a report of your model.

My model is very simple, so everything is green. If anything is yellow, be sure to pay close attention. This could cause you issues within the SCE/IPC. The question mark to the right often has good information.

Finally, green arrow back, press generate, and you have your RTV.

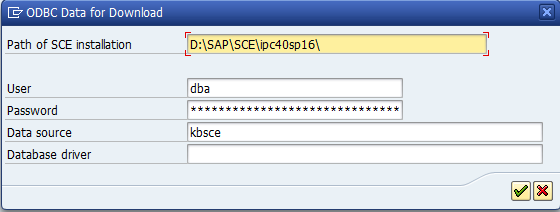

The last step is just to download the flat files.

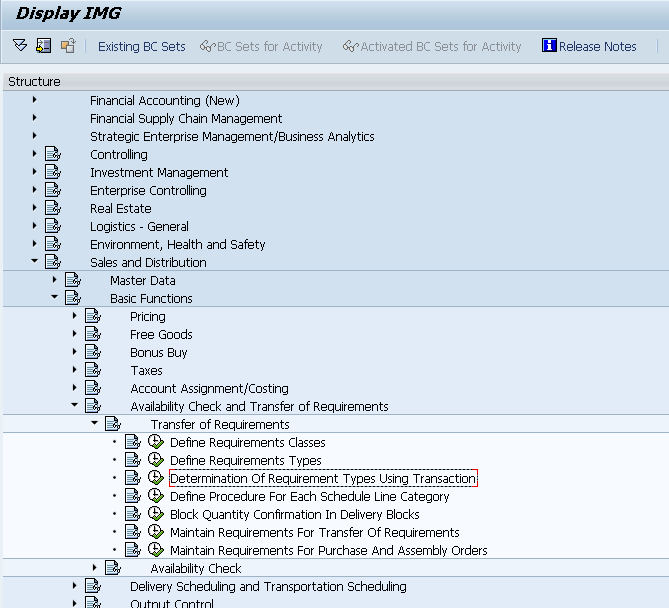

Use transaction CU36

Enter in your KB and version, then press the export button.

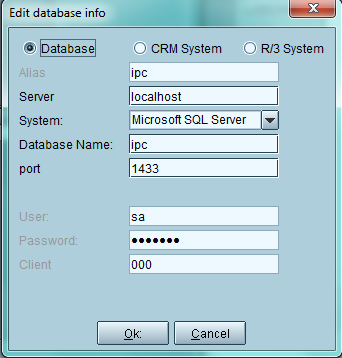

The only field you need to be concerned with here is the Path. the rest only applies if you are using R/3 or CRM as the your SCE installation. For my purposes, I’m focusing on the offline database only.

Hit the green check and you’re ready, Next post I’ll talk about uploading the flat files into the SCE.

Thanks for reading,