It’s been a while since I talked service, so I thought I’d start posting some simple tips and tricks again. In case you forgot, and if you read my blog often you might have, I’m actually a functional consultant, not a basis guy =) Service and VC are favorite areas to work in. I think they provide an interesting set of challenges and are often areas where it is hard to find good people (which is awesome for me). Anyway, I’m working on a 5 – 10 part course talking about the basics of service management. I haven’t decided how long it will end up being, so stay tuned. I have so much in the hopper, but I want to actually show you guys I do know something about SM, service availability.

Today, I want to talk about Service Availability. I’ve seen it used sporadically in places, but never very well. So I want to talk about the how and why. Now, before I get into the meat of the topic, let me explain why this part is important. Just as in sales, knowing if all of the components are available is extremely important to managing your workload. SAP provides the same availability functionality in the service order as it does in the production (except of course, running it in mass… but for that, check Armory by JaveLLin Solutions. couldn’t help the shameless plug). Transaction IWBK is actually a good transaction to show you all of the availability associated with a service order, and it even gives you fancy traffic lights to let you know at a glimpse if everything is available. In addition, the status of the service order itself lets you know if all components are available.

Now, you may be asking, why do I care? Often you have a decent workload of service orders and you require components in order to begin work on them. Wouldn’t it be nice to see at a glance if all the components are available to know if you should start working on the order? Perhaps you released the order to get some MRP requirements out there for parts. Well, if you don’t know when the parts are available, how do you know when you can start working on the order? Meanwhile, the clock is ticking for getting this part back to the customer. Your metrics look worse and worse, all because you don’t know if you have parts to start working on a repair.

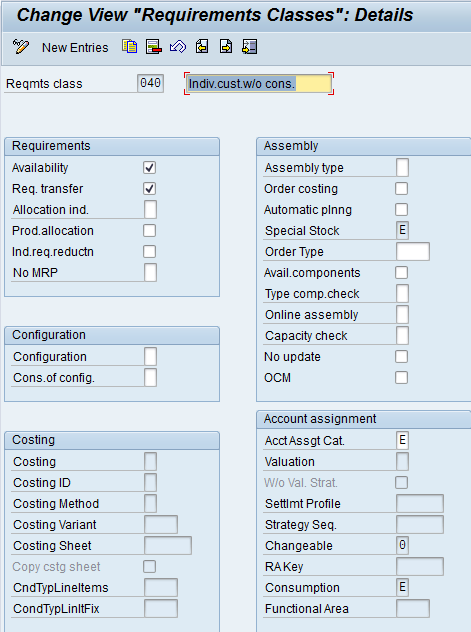

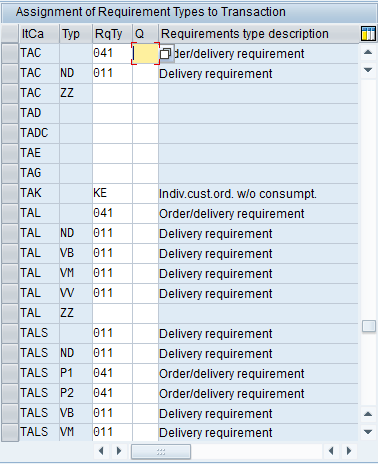

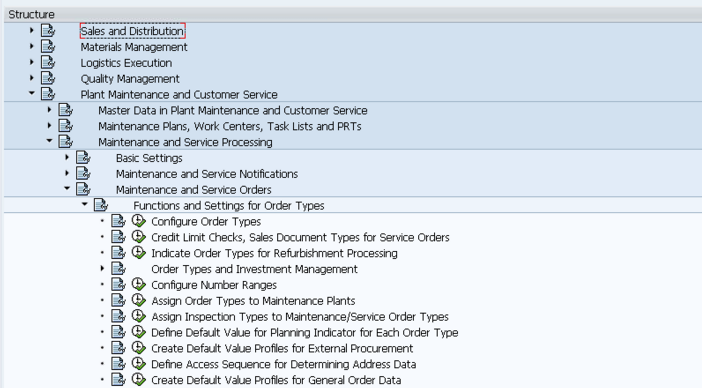

Alright, you understand the problem, so what can you do about it? First thing you need to do is make sure the availability check is configured the way you need it. Just like the availability for sales and production orders, you can have a unique one for service (or more often you’ll use the same one that production uses). The screen shot below shows you were to find the configuration to see what in the system.

If you look at the Define Checking Rules, you’ll see the following. Please note, SM is the default.

Next go the Define Scope of Check… this is where the real work is done.

Remember, that the scope of check can be different depending on the material availability check.

This example shows 02 – SM

Every one of these options determines things that either availability includes or excludes. Every organization is different, so I can’t tell you there are default settings to use. I can tell you that you should experiment with whatever you do select. Have a service order with some components and make sure your settings do what you expect. ATP is touchy… powerful, but touchy… in my e-class, I’ll go into more details about the exact settings.

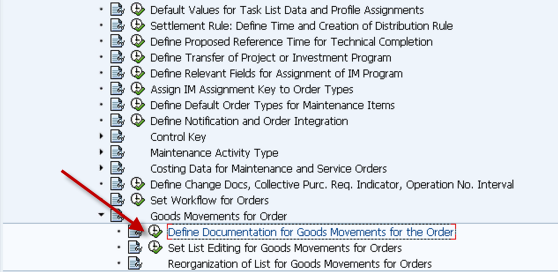

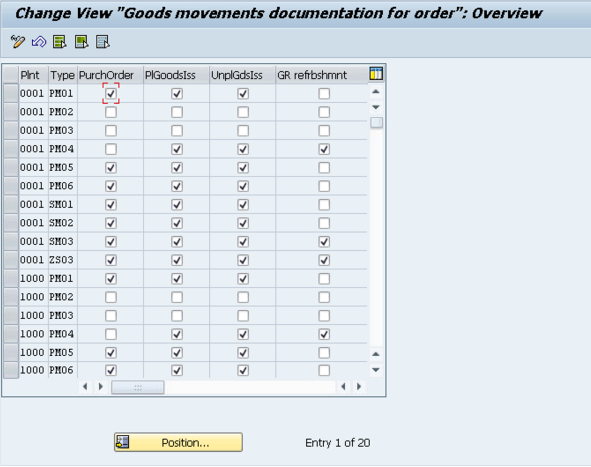

finally, you need to assign the availability check to the plant/order. And you also can change the check for creation vs. release.

Here’s the settings you can control:

Alright, now that you’ve seen where to configure the availability check, you should understand how to run it…

Well, it’s pretty simple. SAP only offers one place to execute availability. IW32.

Press this button to availability. There are several important system status that relate to availability:

MANC – Availability not checked

MSPT – Missing parts

MACM – All parts Available

If you use IW38/IW39 or Iw72/Iw73 and you look at system status, this will give you the quick look to determine if you have components available or not. Please note, this doesn’t do a hard allocation of the components. it simply says, based on the availability check (see above) that it is in stock.

I hope this little overview gives you an understanding why availability could be an important piece of service that you’ve overlooked.

Thanks for reading,

Mike