Thanks to all of you that have commenting on some of posts. I recently got a comment that I figured would be better to do a post on, rather than just answer the question. It’s interesting, because the question that came up seems like it would be pretty standard, yet I haven’t run into the actual scenario before. The scenario is that I have a part with a vendor warranty. The part comes back to me, I fix it and return it to the customer. then I need to invoice the vendor for my repair since it was under their warranty.

Initially, when I looked at this scenario, I thought I could avoid the warranty claims altogether. I was hoping for a simple credit memo generated from the repair line. But you can’t change the partners here since it’s a sub-line item. If it were me, I would want to maintain the history, so keeping my document flow together is ideal, maybe even critical depending on the business needs. This leaves me with 2 options.

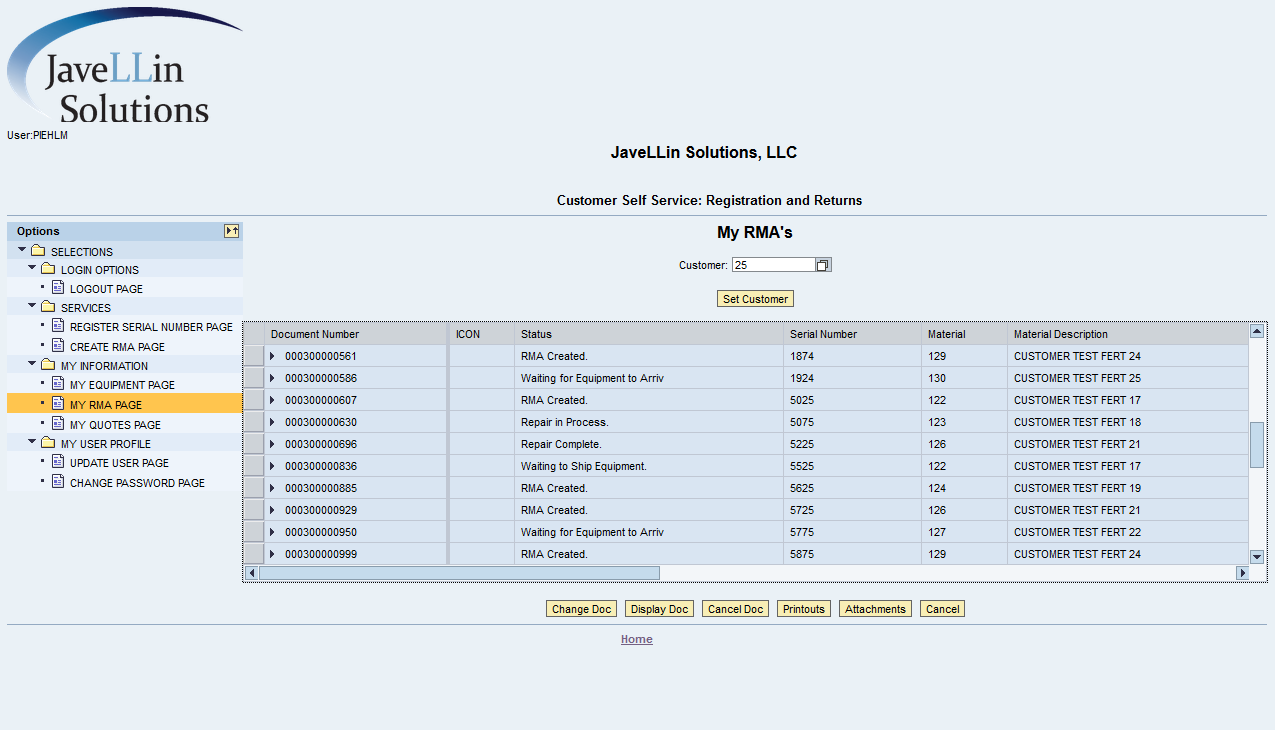

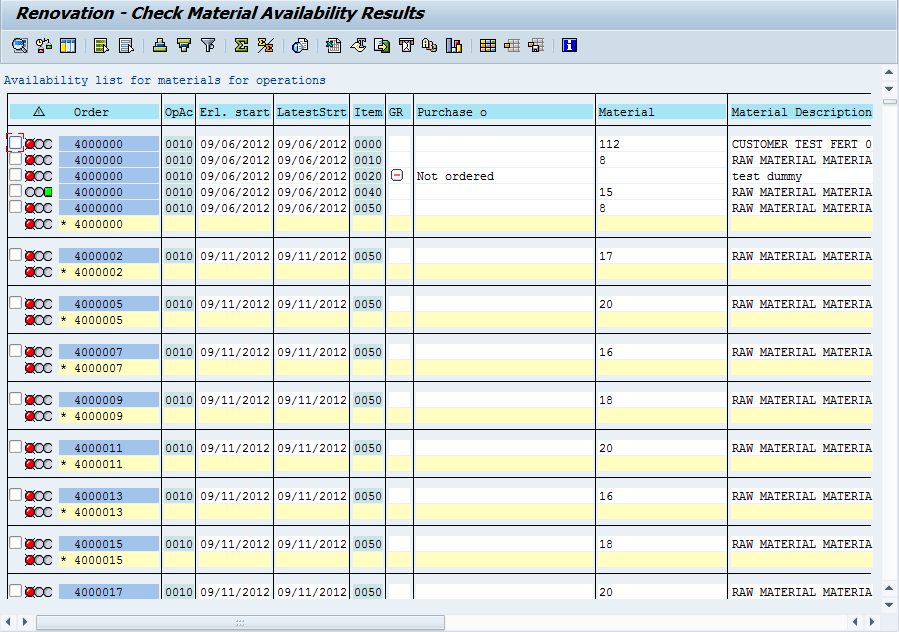

The first option is what I’ll call the quick and dirty method. This process will have gaps that might cause headaches, but it depends on how often this occurs, and of course the terms of the warranty. This process would be to create a credit memo request with reference to repair sales order. Now, in the copy control, you’ll first need to allow this. You may even consider generating a new document type specifically for vendor reimbursement. Now, the gotcha’s begin to happen when you need to work with a vendor, that may or may not have a corresponding customer master to assign to the document. If you’re lucky, there is a customer master, and then this process will work for the easy stuff. Now, the issues will arise when your credit memo to the vendor doesn’t match what they will reimburse. Say for example, they only reimburse parts, but not labor. If you invoice for the full amount, they may reject parts, forcing you to cancel documents, or make changes and then reissue the document, just to get paid. In addition, you will want to make sure you assign the technical object to the credit memo request to make sure the serial number history is maintained. As you can see, there quite a few places for this process to go wrong. However, in a small shop where this doesn’t happen often, this may be a viable solution.

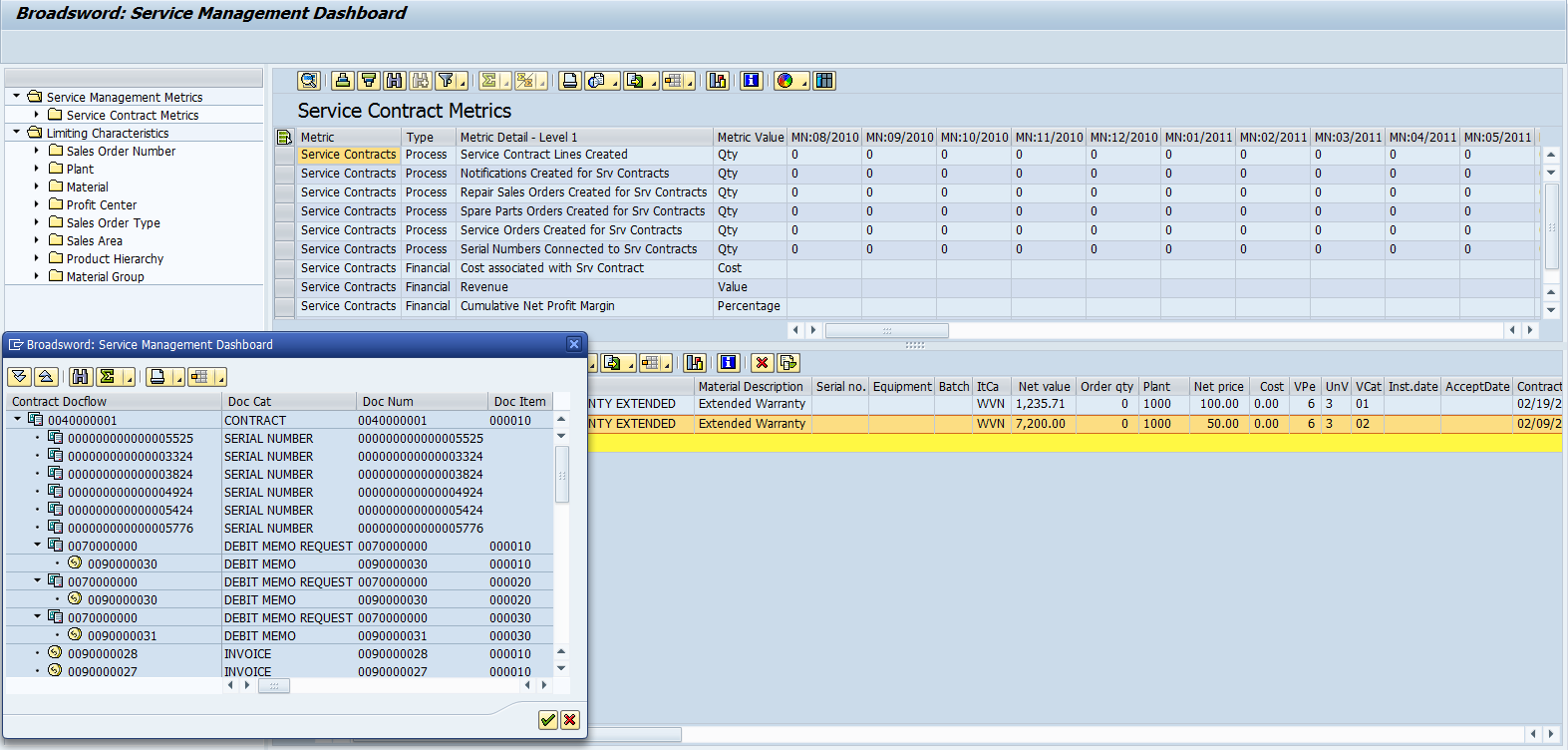

The alternative solution I’d implement is using Warranty Claims. Now, the problem with claims is that they can be complicated and master data intensive. But it will give you the greatest amount of flexibility and reporting. (keep in mind, I haven’t configured this, so I apologize if miss something). I would implement a post-crediting scenario. I would send the reimburse the details of labor/materials/etc. along with the total amount I want to reimbursed. Now, you won’t need to worry about interacting with the customer who owns the product. They will deal with you through the standard return and repair scenario in SAP (since you probably already have a notification, be sure to attach it to the initial claim to be sure you maintain traceability). If you look at my original post on warranty claims for beginners, this scenario will only need to be configured with version 2 & 3 shown in that post. So when you configure the scenario, you don’t need to worry about the version 1 & 4, since you don’t need to deal with the customer, this is purely a reimbursement from the vendor to you. You could go the full way, but I don’t believe it’s needed to accomplish everything needed for this scenario.

Some things to remember, each vendor must be assigned a customer master (just the way this works). And those customers must be assigned the AS partner type to make them eligible for claims processing. You won’t be able to avoid this master data setup.

I’ll be sure to prototype this before I finish writing my book on Warranty Claims 🙂

Thanks for reading,