This is another post I did a long time ago. I even devoted quite a few pages to this in my book. In many of my past implementations, this was something that not enough customers took advantage of. So consider this a subtle reminder of the cool things available in ECC.

Today, I want to talk about Service Availability. I’ve seen it used sporadically in places, but never very well. So I want to talk about the how and why. Now, before I get into the meat of the topic, let me explain why this part is important. Just as in sales, knowing if all of the components are available is extremely important to managing your workload. SAP provides the same availability functionality in the service order as it does in the production (except of course, running it in mass… but for that, check Armory by JaveLLin Solutions. couldn’t help the shameless plug). Transaction IWBK is actually a good transaction to show you all of the availability associated with a service order, and it even gives you fancy traffic lights to let you know at a glimpse if everything is available. In addition, the status of the service order itself lets you know if all components are available.

Now, you may be asking, why do I care? Often you have a decent workload of service orders and you require components in order to begin work on them. Wouldn’t it be nice to see at a glance if all the components are available to know if you should start working on the order? Perhaps you released the order to get some MRP requirements out there for parts. Well, if you don’t know when the parts are available, how do you know when you can start working on the order? Meanwhile, the clock is ticking for getting this part back to the customer. Your metrics look worse and worse, all because you don’t know if you have parts to start working on a repair.

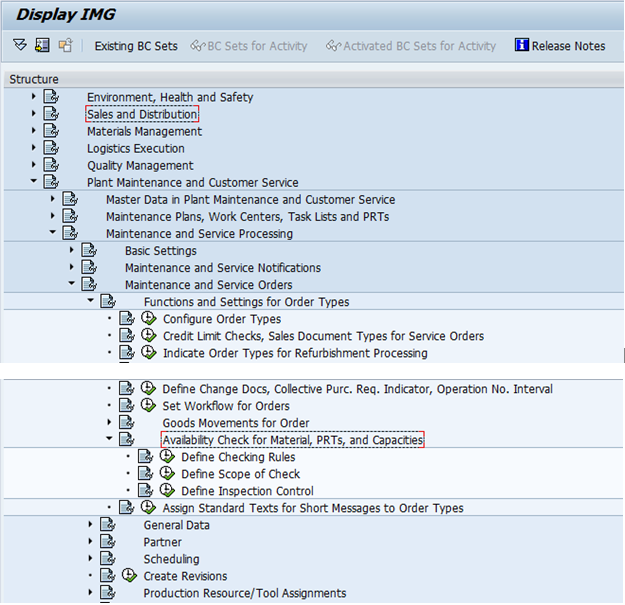

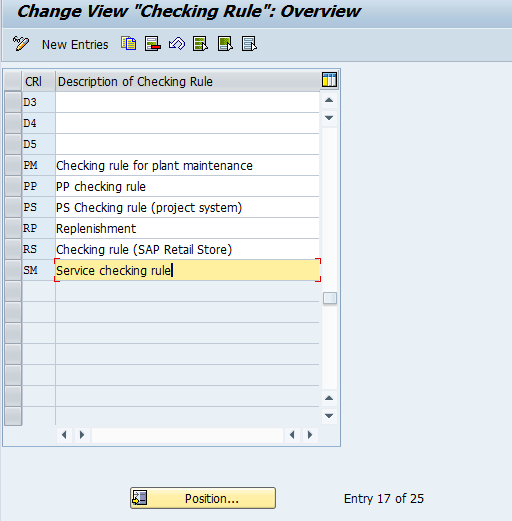

Alright, you understand the problem, so what can you do about it? First thing you need to do is make sure the availability check is configured the way you need it. Just like the availability for sales and production orders, you can have a unique one for service (or more often you’ll use the same one that production uses). The screen shot below shows you were to find the configuration to see what in the system.

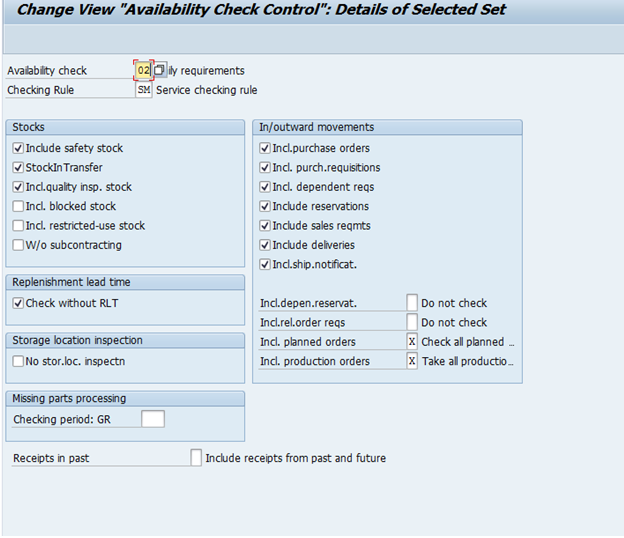

Next go the Define Scope of Check… this is where the real work is done. Remember, that the scope of check can be different depending on the material availability check. This example shows 02 – SM

IMG->Plant Maintenance and Customer Service->Maintenance and Service Processing->Maintenance and Service Orders->Functions and Settings for Order Types->Availability Check for Material, PRT’s, and Capacities->Define Scope of Check

Every one of these options determines things that the availability check includes or excludes. Every organization is different, so I can’t tell you there are default settings to use. I can tell you that you should experiment with whatever you do select. Have a service order with some components and make sure your settings do what you expect. ATP is touchy… powerful, but touchy… I’ll go over the basic of this screen, so you have some idea where to start. My best recommendation will be find out what is working for your production group and start there.

Stock Section: I don’t claim to be an availability expert, but I know the setting well enough to explain the basics.

- Include Safety Stock – This means that safety stock should be considered as available in the availability check. In most organization I see this checked.

- Stock In Transfer – Include stock that is being transferred into the plant

- Include Quality Inspection Stock – Include stock in quality inspection. Normally, I see this NO selected.

- Include Blocked Stock – Just what the name says. Again, not normally checked.

- Include Restricted Use Stock – Include restricted use batch stock. Not normally checked.

- W/O Subcontracting – exclude any vendor or subcontract stock from the check.

Replenishment Lead Time

- Check without RLT – This one is always confusing. You check the box if you DO NOT want to use replenishment lead time from the material master. It depends on if you want availability to find a date, even if none are in stock. Typically in SM, I see this checked.

Storage Location Inspection – this allows you to turn off the storage location check and look for stock only at the plant level.

In/Outward Movements

- Include purchase orders – just what it says. Checked by default.

- Include purchase Reqs – just what it says. Checked by default.

- Include dependent reqs – should it include a requirement that is generated from an upper level demand. Checked by default.

- Include reservations – just what it says. Checked by default.

- Include Sales requirements – include demands from sales orders. Checked by default.

- Include deliveries – include deliveries. Checked by default.

- Include Shipping Notifications – not checked by default.

- Incl.depen.reservat. – take dependent reservations into account.

- Do not check – DEFAULT

- X Include all reservations

- A Only include withdrawable reservations

- Incl.rel.order reqs – take stock transport orders/requests into account.

- X Yes

- No – DEFAULT

- Incl. planned orders- if you don’t take these into account demands from planned orders (potentially placed before this order) will not be taken into account. Stock could be stolen from a planned order if you don’t take this into account.

- Do not check

- X Check all planned orders – DEFAULT

- A Check firmed planned orders only

- B Only check planned orders that are completely confirmed

- Incl. production orders- if you don’t take these into account demands from production orders (potentially placed before this order) will not be taken into account. Stock could be stolen from a prod order if you don’t take this into account.

- Do not take into account

- X Take all production orders into account – DEFAULT

- F Only take released production orders into account

This is probably enough for now. Next time I’ll show you how to finish up the configuration, and more importantly, how do you use this once it’s configured.

thanks for reading,