I recently had a friend of mine ask me about how to deal with a situation that made me instantly think about service contracts. Like so many thing in SAP, standard service contracts have a lot of possibilities, but can require some work. That made me think that I should do a post on SAP Service Contracts. So here goes.

SAP Contracts are a very versatile sales document in ERP. Some of the things you can do with contracts include:

- Start and end dates by line item.

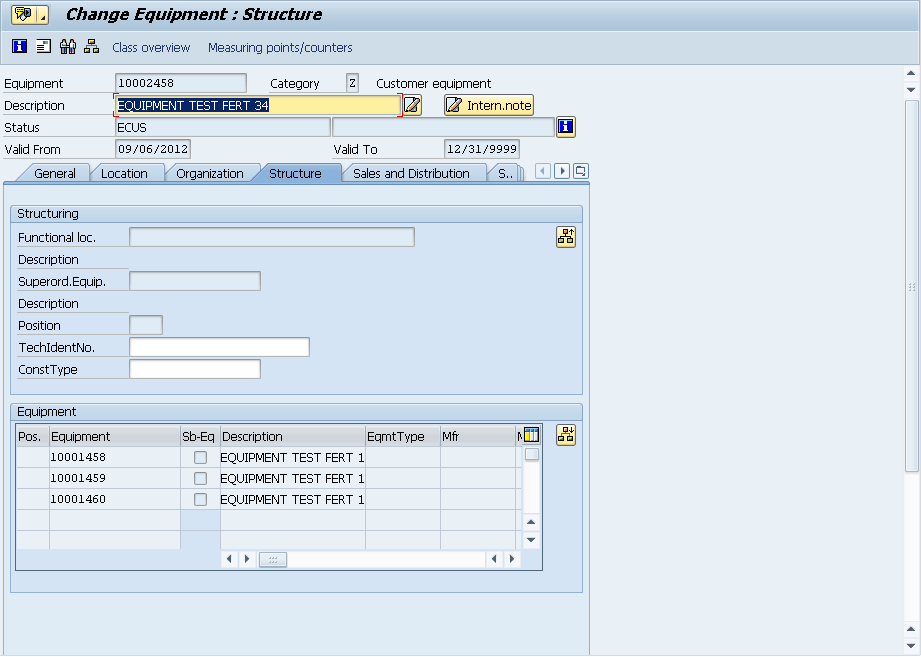

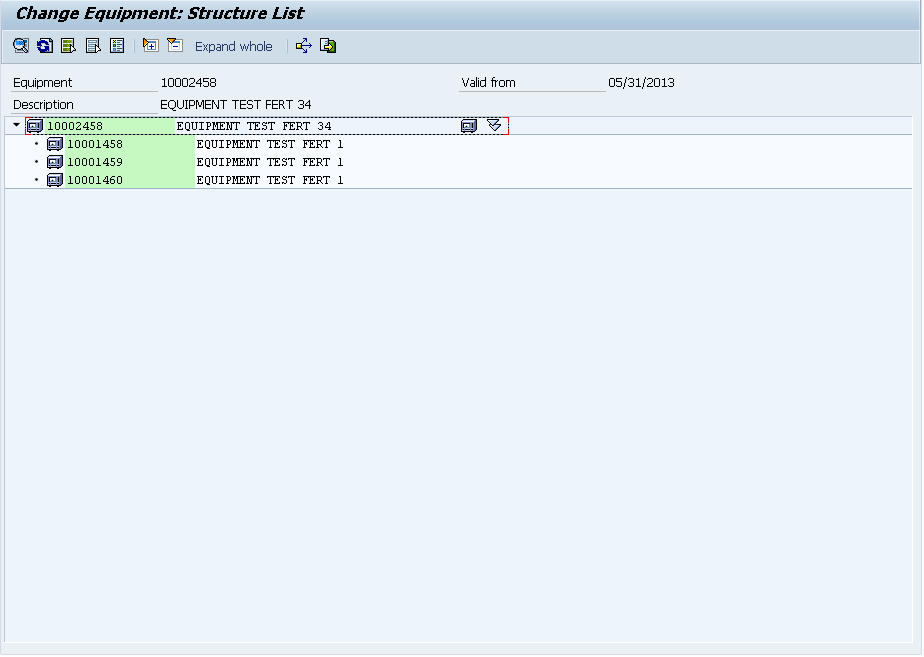

- Ability to connect multiple technical objects to a contract line item.

- Ability to connect a billing plan to bill at any interval the customer needs.

- The ability to recognize revenue on a particular line item, either at a time based or milestone basis.

- The ability to connect to any document in the document flow. Notifications, repair sales orders and call off orders are the scenarios just to name the most popular.

- The ability to directly kick off a service order from the contract (given the correct item category). This allows for easier profitability analysis for a contract due to settlement rules that can settle directly to the contract. This would work in the same way that the current field service sales order behaves.

Contracts also provide a mechanism to see if the contract is making or losing money. This is typically accomplished using custom reports. The custom report is usually required since service orders typically settle to the repair sales order and normally companies will want to do analysis on all contracts for a particular materials/profit center/product hierarchy/etc to determine the contract tends. Using document flow, you can quickly gather all repair sales orders or direct service orders connected to the contract and sum all the values.

Contracts also have several out of the box reports that can be run at any time:

- VA45 – Contract List (this will behave like VA05)

- VA46 – Collective Subsequent Processing of Contracts

- IW74 – Change of Servicable Item Contract

- IW75 – Display of Servicable Item Contract

- V.06 – Display incomplete contracts.

- SDV1 – Expiring Contracts

- SDV2 – Expired Contracts

- SDV3 – Completed Contracts

Maintenance Contracts Items

The maintenance contract is used for general service over a time period. An example of some things you would use a maintenance contract for:

- Extended maintenance where all parts and labor are covered for 1 year.

- Unlimited tech support calls or emails.

The maintenance contract is very useful when you don’t have a limit to the number of times a customer can request service. You can still follow the standard repair process, field service process, or even just create a notification in order to track the services provided. Typically, a maintenance contract is invoiced only from the contract, unless the terms and conditions state that all parts must be paid for by the customer or any other variation like that. In those instances, it may be required to use time and expenses billing on the repair sales order (using the DIP profile) rather than flat rate pricing.

Quantity Contracts Items

The quantity contract is used for any service that you are selling in a limited quantity. An example of some quantity contracts may include:

- 3 calibrations to be used any time over the next 3 years

- Yearly onsite inspection

- 5 repairs for any of 5 pieces of equipment over the next 3 years.

The quantity contract is useful to keep track of how many service calls a customer has paid for in advance. It can also be easily tied into revenue recognition (milestone). Each time a call off order is created with reference to the quantity contract item, it can signal revenue recognition that the item has been used and can now be moved from deferred revenue. You can also quickly look at the quantity contract and see how many items the customer has outstanding. Please note, this is a dynamically generated quantity field, so you will not be able to pull this field directly from a table if you are doing any custom reporting.

There’s a lot more about contracts, and if you have specific questions, I’d love to hear from. Thanks for reading.