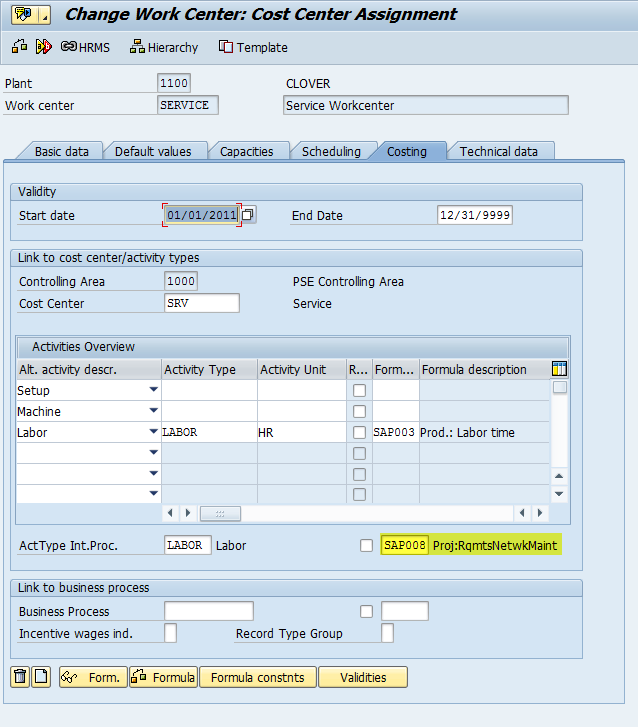

Now this is one of the few tricks that I’ve picked up when it comes to the finance portion of the world 🙂 And the only reason I care about this is because it simplifies my configuration for service order costing and also resource related billing. The concept is called Cost Element Groups. And they are exactly what they sound like, a group of cost elements. Now, why do I care? in both service order cost display and resource related billing, I can enter each cost element into the configuration, transport it, and call it good. Now, when a new cost element is suddenly introduced, I now need to go back to my dev environment, make sure the cost element exists, then add it to my configuration again, and transport everything. Cost Element Groups let this all be controlled through master data. I connect the cost element group one time, and I’m covered for life. so, let me show you how easy they are, and you can be the judge.

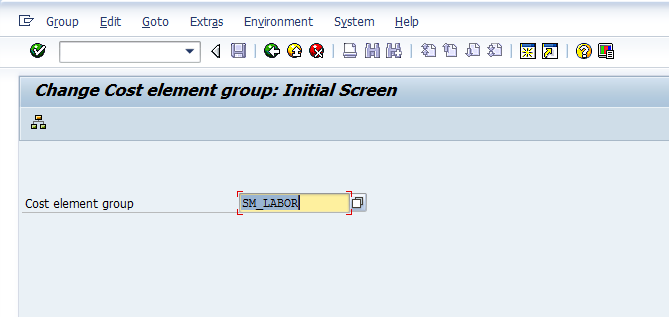

Everything starts with transaction KAH1/KAH2/KAH3. Below, I’m showing you KAH2 for an existing cost element group, but it’s basically the same for any of the create/change/display transactions.

Enter in the name of the group and hit enter, or the hierarchy button.

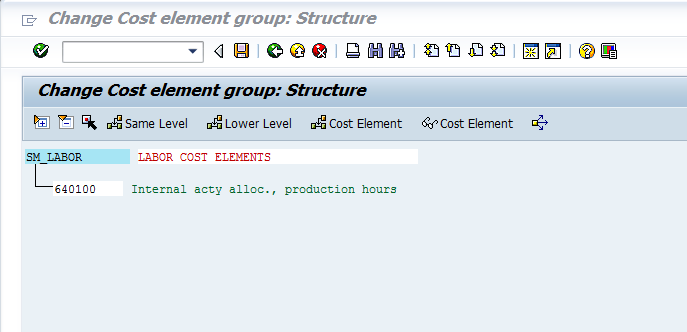

This will bring you to the above screen. You can add or change the name of the group, then press the Cost Element button.

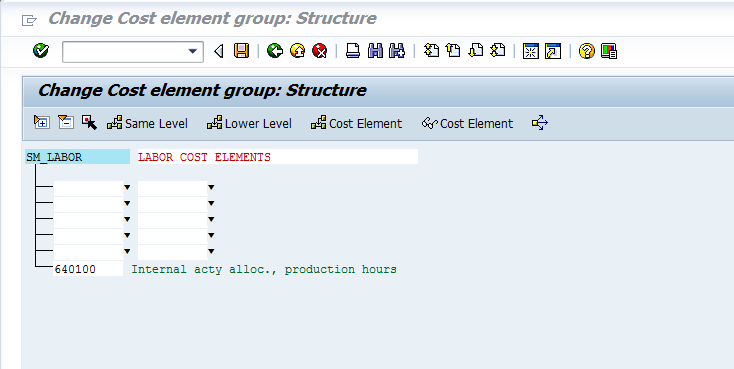

Once you press the button, you will see some new blanks show up. You can either enter in individual cost elements (just enter the number in the left column) or you can do a range, by entering the start in the left and finish in the right. Then it will show you all the cost elements that were located within the range.

Simply save, and you’re ready to go. Now, you do need to remember to create this master data in every system you want to use it, but the flexibility is worth the master data effort.

Thanks for reading,