I’ve recently been helping out a fellow service expert to navigate the ins and outs of quoting service. It really has lead me to the question “why is it so difficult?” Let me tell you where I’m coming from, in the ECC world, if you want to quote your customer for In-House Repairs, you have to jump through a lot of hoops. First, you have to decide if you want to go with a more manual approach, or do a bunch of “SAP sponsored” development. Each of these methods as merit, but at the end of the day, if you want send a quote to your customer, it’s not easy.

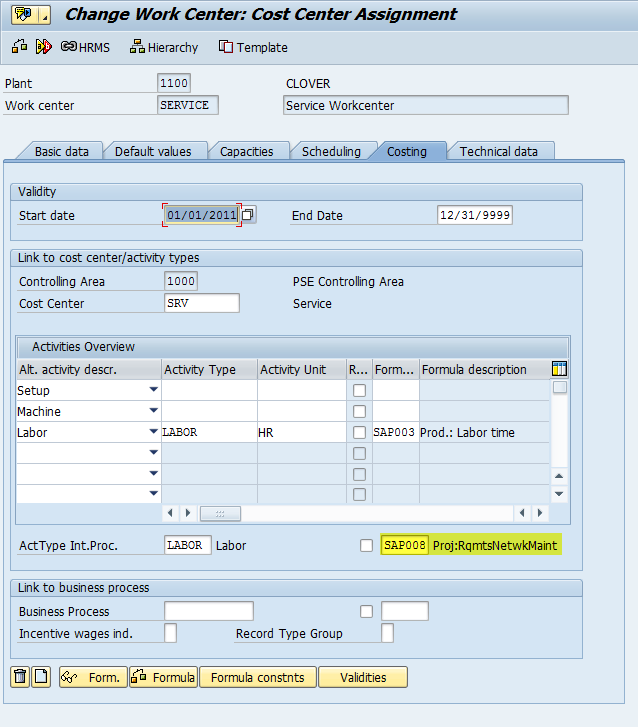

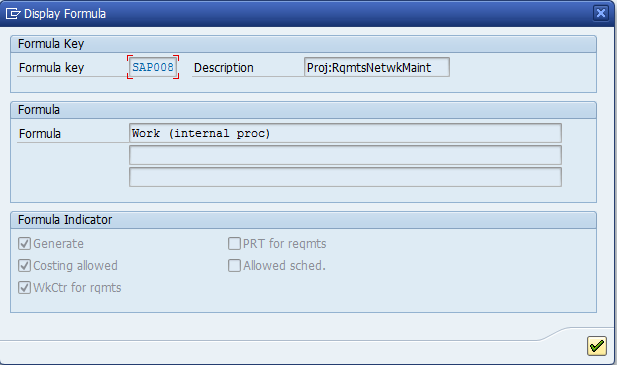

A while back, I did a post that explained the SAP approved method for handling this. It entailed new item categories, users exits, DIP profiles, and of course, a lot of form and pricing work. Overall, it’s a pretty slick method, but it requires a lot of ramp up to get there, and for non-SAP experts, it can look very cluttered and cumbersome. The long and short of it is that your sales order because both the sales order and the quote. Does it work? absolutely. Is it an elegant solution… in my opinion, absolutely NOT.

The flip side is to simply create a quotation with reference to the original sales order. This means that you basically have to enter in the quote from scratch. You will need your service guys to send you an excel, or you need to be fluent enough in reading a service order to enter in all the data. Minimal development effort… maximum effort from the users.

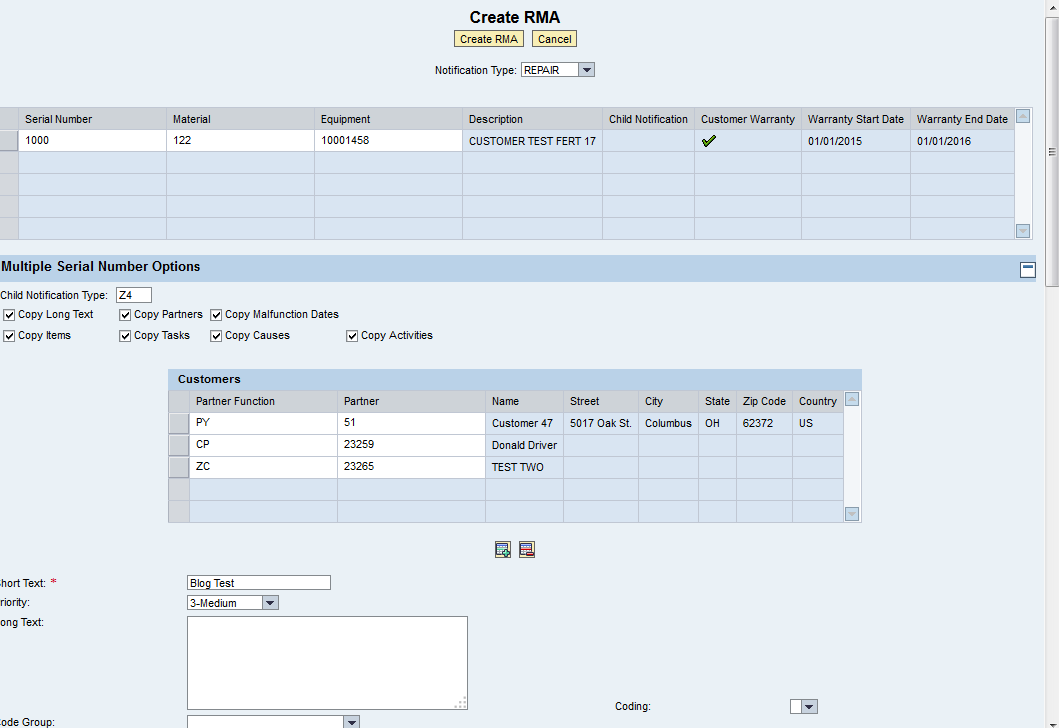

This lack of good options lead me to create a simple button in Renovation: Repair Order Execution. The button is simply Create Quotation. What isn’t simple is the cool functionality behind this button. First off, it checks for a specific user status on the service order to make sure the service department has finished updating the order with planned cost. Next off, it check how you want you quote created. Do you want the servicable material as an item on the quote? do you want all the items that would have come from you DIP profile? do you want to pull from a sales bom? Then it pulls in the items on the order, and then adds the unit costing for each thing, so that EK02 condition will show you the cost. Then, to let the service department know what’s going on, it changes the user status to show that they are waiting for the customer to accept or reject the quote.

If you are interested in a better way to quote for service, check out Renovation. Just email me, and I”ll be happy to set up a demo.

Thanks for reading,